Country: San Diego, Chile

Materials:rice

Packaging requirements:

a.Roll film

b.1kg /2.5kg per bag,35-45bags/min

c.Full automatic feeding/weighing/filling/bag making/sealing

Solution:

A.Feeding part:

KY-Z03 Z type elevator adopts a closed casing design to reduce the contact between popcorn and air; inflow feed, stable and reliable operation of the hopper, low popcorn crushing rate in the whole process, and good integrity. The customer's plant is limited,Z-lift is "horizontal-vertical-horizontal" transportation, saving space.

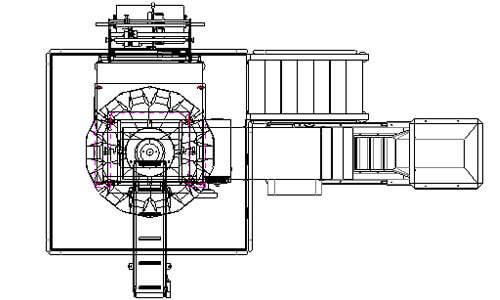

B.Weighing and filling part:

B.Weighing and filling part:

KY-GDJ14-4L Multihead weigher are more suitable for automatic weighing of rice, beans and other granules materials;It adopts vibration compensation, which can reduce the influence of external vibration and weighing and realize high-precision weighing; modular design makes troubleshooting and component replacement easier.

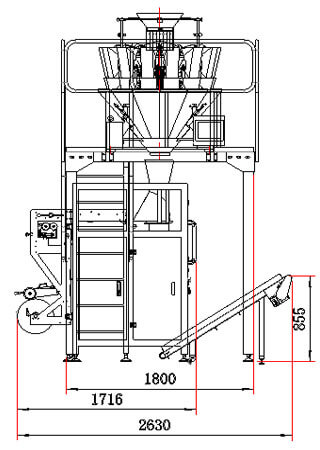

C.Work platform part

KY-PT-05 working platform is mainly used to carry intelligent combination scales, supporting film rolls and other equipment. Made of stainless steel checkered plate, non-slip and wear-resistant; humanized guardrails and stairs to protect workers' construction safety; platform size is customized according to customer requirements, and fits the customer's plant area.

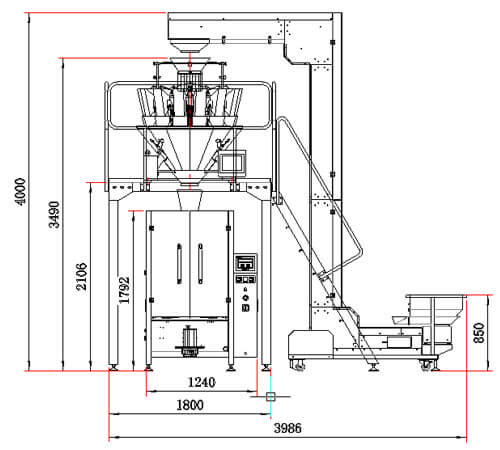

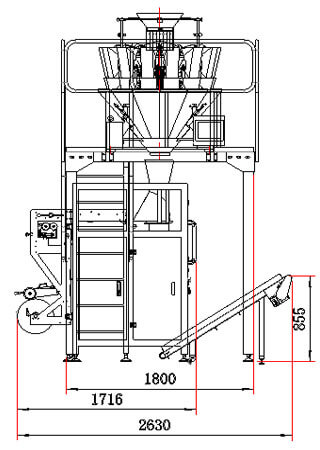

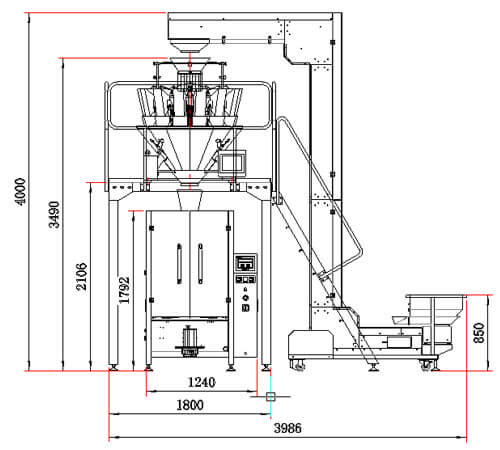

D.Vffs sachet packing machine

KY-620 vffs sachet packing machine adopts imported PLC full computer control system, man-machine interface, large display touch screen, easy operation; servo film transport system, accurate positioning, excellent performance of the whole machine; it is matched with the metering device to automatically complete feeding, bag making, filling, The whole process of date printing, inflation (exhaust), counting, and finished product transportation. It fully meets the needs of customers for fully automated production.

B.Weighing and filling part:

B.Weighing and filling part: